- Products

- Diebel Aluminum Frame Conveyors

- Chain Driven Live Roller Conveyors

- ToughTrak™ Slider Bed Conveyors

- SteelTrak™ Hinged Steel Belt Conveyors

- Slider Bed Conveyors

- Magnetic Conveyors

- Floor to Floor Conveyors

- Drag Conveyors

- Inclined Conveyors

- Slat Conveyors

- Powered Curves Conveyors

- Wire Mesh Belt Conveyors

- Cleated Belt Incline Conveyors

- Gravity Conveyors

- PlastiTrak Plastic Belt Conveyors

- Turntable Conveyors

- Belt-Driven Live Roller Conveyors

- Pallet Handling Conveyors

- Special Application & Custom Conveyors

- Quick Start Electrical Controls & Accessories

- Industries

- Customer Service

- UPtime Express

- Careers

- Get a Quote

Products

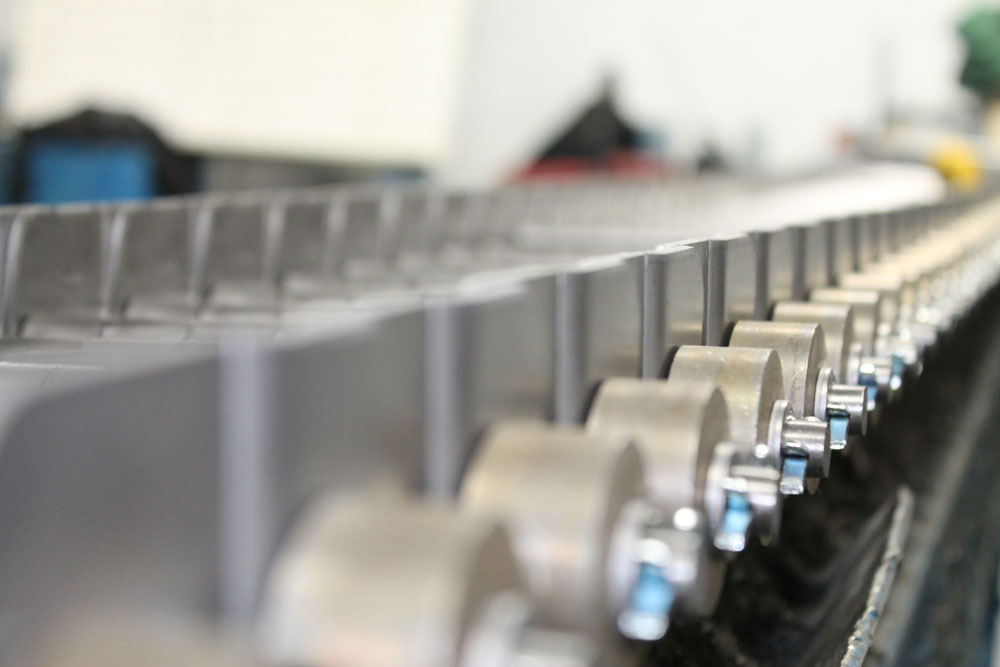

PlastiTrak Plastic Belt Conveyors

Available in two series, 1000 models and 2000 models. New London Engineering’s PlastiTrak Belt Conveyors offer superior performance, flexibility, and productivity. These smooth running systems create a worker friendly environment that allow the free flow on material in production environments. Often used in robotic applications to move material in and out of the automated cells.

Our exclusive ACT (Application Change Technology) provides the safety and flexibility to exchange the existing belt if the application or product changes. The system is designed to provide the room and clearance for various sprocket and belt styles. Just loosen the bolts on the shaft’s “floating” assembly mechanism and then align the arrows to the designated belt number.

Available in horizontals, inclines, curves and combinations of any of the styles for maximum flexibility

Over 50 belt styles available for almost every form of conveying and product type

Customized wear strip design reduces belt friction and extends belt life

Cleated belts can provide efficient product movement through inclines and declines

Sprocket drive eliminates tracking issues

1000 Models

Model 1000 Features

Model 1000 Series plastic chain conveyors are typically used to convey lighter products like packages, bottles, plastic parts and cans. Since product weight for these applications are typically lighter construction features, including a 12 ga frame are standard on this unit. Steel chain options are also offered for heavier loads and commonly used in robot cells moving casings or heavier parts in and out of the cell.

1000-S Straight Running Horizontal Plastic/Steel Conveyors

Designed for straight running applications, this unit is capable of supporting various styles of plastic chains and metal chains. This conveyor is used to carry lighter-weight products common in bottling operations and other packaged goods in a variety of industries.

1000-C Standard Chains For Curved Applications

Used when the application requires right-hand or left-hand curves, the Model 1000-C (curved) is capable of supporting various styles of plastic and metal chains. This conveyor is used to carry lighter-weight products common in bottling operations, packaging applications and pharmaceutical plants.

2000 Models

Model 2000 Features

Model 2000 Series Conveyors are typically used to convey larger items like boxes and cases as well as heavier products like stacks of lumber, ammunition casings, stamped or machined parts. This unit’s durable construction and design includes a 10-gauge frame capable of handling heavier and larger products.

2000-CF Curved and Flighted Conveyors

Used in applications that require curves and elevation changes.

2000-F Flighted Plastic Belt Conveyors

Designed to carry small, unboxed, loose products like plastic parts, nuts, bolts, ammunition casings, cans, and stampings, these units typically use flights (cleats) and sideguards to catch, carry and contain unwrapped, unpackaged items.

2000-N Nose Over Conveyors

This unit designed to carry boxes (packaged items) up inclines or down declines and uses a belt with a friction top surface rather than a cleat to move products. The Nose Over provides a smooth transition from the incline to the horizontal.

2000-S Straight Running Horizontal Plastic Belt Conveyors

Designed for straight running applications, the Model 2000-S is capable of supporting various styles of plastic belts designed to handle general transport applications in light to heavy duty production and packaging operations.

2000-C Curved Plastic Belt Conveyors

Model 2000-C (curved) is used when the application requires right hand or left-hand curves.

Contact us to learn more about our unique product offerings.

Our team is ready to answer your questions and help you with all your conveyor needs.